|

BRAZING COPPER AND COPPER ALLOYS

The principle of brazing is to join two metals by fusing with a filler metal. The filler metal must have a lower melting point than the base metal and greater than 842 degrees F (450 degrees C); use of a filler metal with a melting point less than this is soldering. The filler metal is usually required to flow into a narrow gap between the metals by capillary action. Brazing is used widely for joining copper and copper alloys, with the exception of aluminum bronzes containing greater than 10 percent aluminum and alloys containing greater than 3 percent lead. Establish the correct heating pattern so that the filler metal flows up the thermal gradient into the joint. To prepare the surface, standard solvent or alkaline degreasing procedures are useful in the cleaning of copper-base metals. Be careful when using mechanical methods to remove surface oxides. Chemical removal of surface oxides can be accomplished by using an appropriate pickling solution . Control the distance between the joints to be joined. They must be controlled to within certain tolerances. The tolerances depend upon the brazing alloy and the parent metal used. The best joint gap usually lies between 0.04 and 0.20 mm.

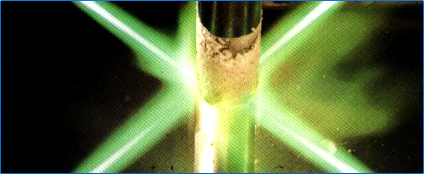

to achieve an adequate bond during brazing, the following points should be considered ...* Joint surfaces must be clean and free of oxides, and provision must be made for the correct joint gap for the particular brazing filler. * Usually a joint overlap of three or four times the thickness of the thinnest member to be joined will work. * The goal is to use as little material as possible to achieve the desired strength. silver brazingUse a neutral flame(one in which equal amounts of oxygen and acetylene are mixed at the same rate). The white inner cone of the flame is clearly defined and shows no haze. Flux residue must be removed. Use one of the following methods: * Adilute solution of hot caustic-soda dip * A wire brush and rinsing with hot water * Wire brushing and steam Incomplete flux removal may cause weakness and failure of the joint.

|